QH5 U

Portable UCI Hardness Tester for metals

The best option to measure tubes, metal sheets and HAZ

The QH5 U hardness testers are ideal to measure metal plates or sheets, tubes or pipes with small thicknesses, small parts in general, heat affected zones (HAZ) in welds as well as heat treated or hardened surfaces among other applications generating an almost invisible indentation.

QH5 U

Outstanding features

Measure with the UCI method

Measures in the most popular units

Accepts 10, 50 and 98N UCI probes

Generate user materials

Sound and visual alarms for maximum and minimum

CalTag: UCI probes with calibration

Memory for 32000 readings

USB for data transfer

Real time histogram graphics

Real time complete statistics

Meets international standards

5 years limited warranty on the electronic unit

UCI Probes

UCI probes allow measurements of small and thin parts and of superficial hardness. They are available with three test loads and choice of the load depends on the surface finish of the test piece.

They offer integrated calibration with CalTag technology to guarantee accuracy.

Select a UCI probe to view additional information.

10N UCI Probe

IIdeal to measure superficial hardness, polished surfaces and small parts with a good finish.

Superficial roughness:

Maximum roughness is Ra 5µm according to ASTM 1038 standard

50N UCI probe

Measure induction or cemented treated parts such as crankshafts, gears, welds and heat affected zones.

Superficial roughness:

Maximum roughness is Ra 10µm according to ASTM 1038 standard

98N UCI probe

Recommended for use in founded parts, weld seams and heat affected zones even in unmachined surfaces.

Superficial roughness:

Maximum roughness is Ra 15µm according to ASTM 1038

10N UCI Probe

Ideal to measure superficial hardness, polished surfaces and small parts with a good finish.

Superficial roughness: Maximum roughness is Ra 5µm according to ASTM 1038 standard

50N UCI probe

Measure induction or cemented treated parts such as crankshafts, gears, welds and heat affected zones.

Superficial roughness: Maximum roughness is Ra 10µm according to ASTM 1038 standard

98N UCI probe

Recommended for use in founded parts, weld seams and heat affected zones even in unmachined surfaces.

Superficial roughness: Maximum roughness is Ra 15µm according to ASTM 1038 standard

Compatible with DataCenter

All models allow you to connect to a PC where data can be processed using our dmq DataCenter software available at no cost.

See DataCenterApplications

Ideal to measure and control:

- Metal sheets and pipes

- Small and thin parts

- HAZ or heat affected zones in welds

- Crankshafts, Camshafts, Gears

- Superficial treatments

QH5 U general specifications

Dimensions

79 x 117 x 32mm

(3.1 x 4.6 x 1.26in)

Weight

182g

(0.40lbs)

Materials

Steel

Aluminum

Copper

Brass

Hardness units

Vickers

Rockwell C

Rockwell B

Brinell

Shore

Mechanical strength (N/mm2)

User units 1

Resolution

1HV

0,1HRC

0,1HRB

1HB

0,1HS

1N/mm2 (Mechanical strength)

Measuring Range

HV 100 - 950

Accuracy

+/- 5% in the entire HV measuring range

Power

AA x2

Battery Life

150 Hours (Aprox. without light)

Certificates and International Standards

Certificate of Conformity

Marcado CE

ASTM A1038

DASTM E140

1. User can set units for measuring materials not included in equipment list.

2. Display light off.

Ready to use

Delivered in a high impact carrying case, inside you will find:

- QH5 U electronic unit

- Certificate of conformity

- UCI probe

- Printed user manual

- HV Reference test block

- Cable USB para conexión a PC

- Coupling paste for parts

- Pendrive with dmq DataCenter software

Hardness measurement with the UCI method - QH5 U

What's inside the QH5 U

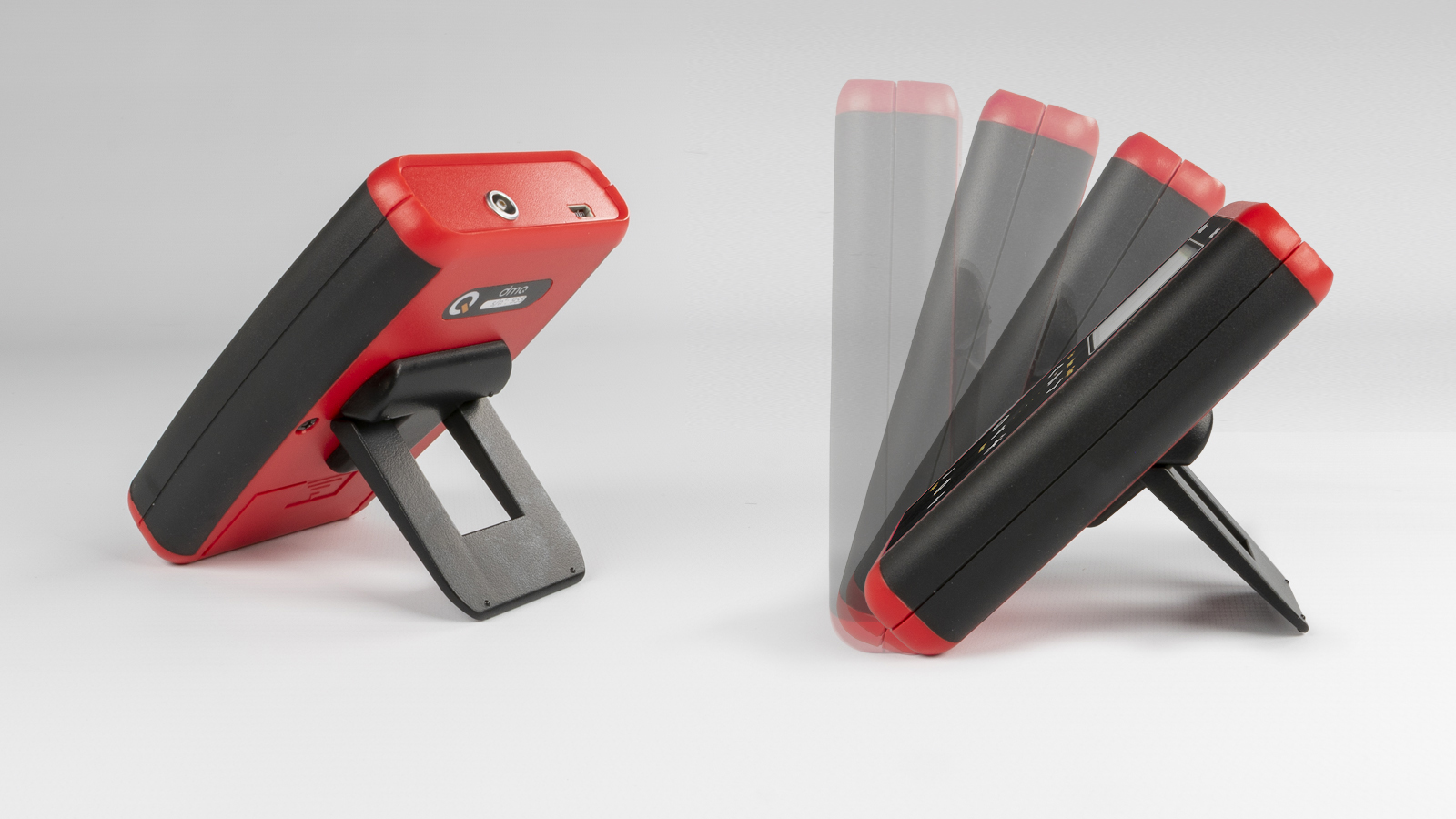

QH5 U electronic unit - Front and Back

QH5 U electronic unit - Power supply: AA x2

QH5 U electronic unit - Connectors detail

QH5 U electronic unit - Tilt Feet

You can find more videos in our YouTube channel.

Go YoutubeAccessories and Consumables

QHS110

10N UCI Probe

Ideal to measure superficial hardness, polished surfaces and small parts with a good finish.

Superficial roughness: Maximum roughness is Ra 5µm according to ASTM 1038 standard

QHS150

50N UCI probe

Measure induction or cemented treated parts such as crankshafts, gears, welds and heat affected zones.

Superficial roughness: Maximum roughness is Ra 10µm according to ASTM 1038 standard

QHS198

98N UCI probe

Recommended for use in founded parts, weld seams and heat affected zones even in unmachined surfaces.

Superficial roughness: Maximum roughness is Ra 15µm according to ASTM 1038 standard

QHG005

Coupling paste 50 cc / 1,76 oz

Coupling paste for use with lightweight parts.

Calibration and Traceability certificates available for reference test blocks. See Certifications section.

HB, HRB, HRC and HV reference test blocks

- QHR201: Rockwell C (HRC) reference test block

- QHR301: Rockwell B (HRB) reference test block

- QHR401: Brinell (HB) reference test block

- QHR501: Vickers (HV) reference test block

Inquire.

YAMAMOTO brand test blocks

- YHR201: Rockwell C test blocks (HRC)

- YHR301: Rockwell B test blocks (HRB)

- YHR401: Brinell test blocks (HB)

- YHR501: Vickers HV10 test blocks (HV)

Inquire.

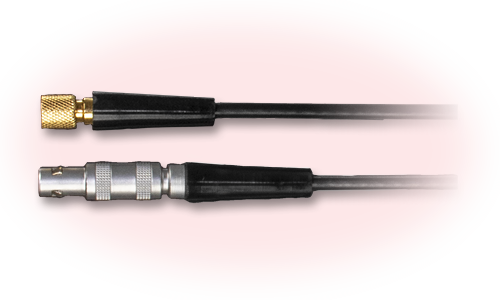

QHC105

Cable with connector for all dmq UCI probes

Cable with a Lemo 0B and a Microdot connector.

QAC001

Cable to connect a thermal printer to dmq instruments

Adapting cable with mini USB to mini USB connectors.

QAI001

Thermal printer for dmq instruments 3

Speed: 90mm/s

Resolution: 203dpi

Weight: 134g

Dimensions: 105 x 75 x 45mm

3. Does not include connecting cable

QHP001

Silicone protective cover

Color: Red

Certificates and International Standards

Included certificate

Certificate of Conformity

This certificate accompanies all DMQ equipment, they are made based on secondary reference test blocks, procedures and internal DMQ standards.

- QHF311: Certificate of Conformity for Electronic Unit with UCI method on Vickers test block

Optional certificates

Optionally, we offer Calibration certificates and Certificates with traceability for reference test blocks:

Calibration Certificate

Certificate issued by an external laboratory accredited by INTI-SAC, expressing the results of the calibration of the instruments or reference test blocks according to ISO/IEC 17025.

Check validity of the certifying organization in your region.

- QHF121: INTI-SAC Calibration Certificate under ISO/IEC 17025 IRAM 301 standard for HV scale Vickers reference test block

Certificate with Traceability

Additional certificate based on instruments or reference test blocks certified by INTI-SAC laboratory, a copy of the traceability certificates is attached to the traceability certificate.

Check validity of the certifying organization in your region.

- QHF222: Certificate with INTI-SAC Traceability for Vickers reference test block on HV scale

International Standards

CE Marking

ASTM A1038 / ASTM E140

Model: QH5 U

I am Quokke, the  mascot.

mascot.

Choose us and be as happy as I am!

See products

QH5 U

Portable UCI Hardness Tester for metals

Contact Us

Request Quotation